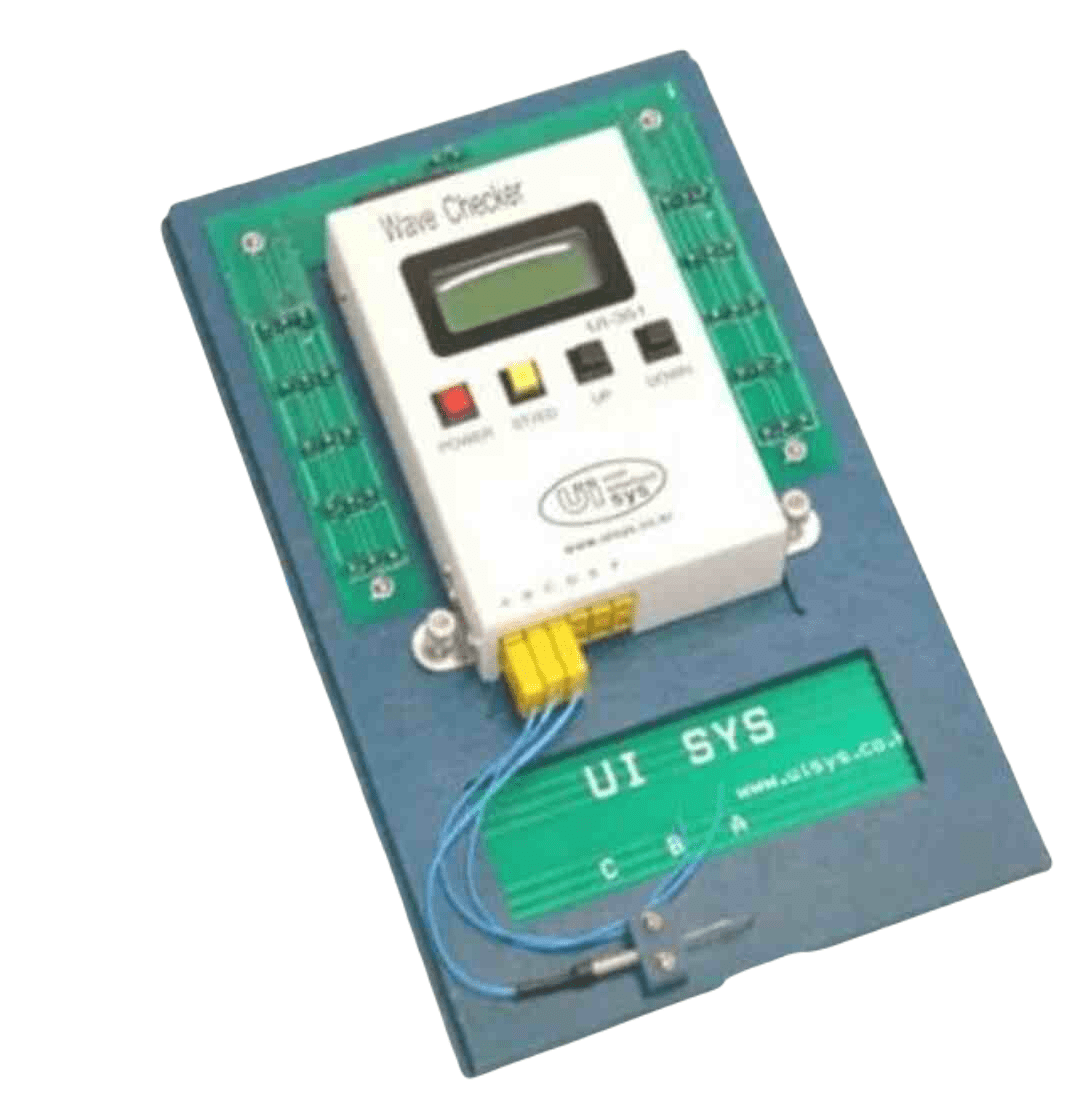

Wave Checker

Supplier in Delhi | Kaasu Enterprises

Wave Checker

Product Details –

| Parameter | Description |

|---|---|

| Product Name | Wave Checker |

| Category | SMT Product |

| Function | Measures and verifies wave soldering process consistency |

| Applications | Wave Soldering Machines – Temperature & Wave Height Monitoring |

| Display | Digital LCD Display with Real-Time Measurement |

| Key Features | Precise Wave Height Detection, Process Optimization, Easy Calibration |

| Usage | Ensures stable solder wave, reduces defects, improves quality control |

| Power Source | Rechargeable Battery or USB Powered |

| Material | Durable Heat-Resistant Construction |

| Data Output | USB or SD Card Data Export (varies by model) |

Wave Checker: A device used to measure wave solder quality and parameters during the soldering process.

Kaasuenterprises Provide The Best high quality Equipments, Tools, consumables and Materials for the Electronics manufacturing

Kaasuenterprises, we are dedicated to empowering industries by providing cutting-edge technological solutions that enhance productivity, efficiency, and product quality. Recognizing the pivotal role electronics play in today’s business landscape, we strive to be your trusted partner for all electronic equipment and accessory needs.

Additional Information:

Wave Checker – The Key to Precision in Wave Soldering Quality Control

In high-volume PCB assembly, consistent quality and process reliability are non-negotiable. As wave soldering remains a cornerstone for through-hole component assembly, maintaining control over wave parameters is essential. Enter the Wave Checker—an advanced diagnostic tool designed to measure and monitor the wave soldering process with real-time precision.

At Kaasu Enterprises, we provide high-quality Wave Checkers engineered to help manufacturers achieve stable, repeatable, and optimized soldering results across every batch. Whether you’re focused on minimizing defects, improving yield, or enhancing traceability, the Wave Checker is your go-to inspection device.

Product Overview –

Here’s a technical summary of the Wave Checker offered by Kaasu Enterprises:

| Specification | Details |

|---|---|

| Product Name | Wave Checker |

| Category | SMT Product |

| Primary Function | Measures wave height, temperature, and process consistency |

| Applications | Wave soldering line quality assurance |

| Display Type | Digital LCD Display with Real-Time Reading |

| Key Features | Wave Height Detection, Thermal Profiling, Calibration Tools |

| Power Supply | Rechargeable Battery / USB Powered |

| Material Construction | Heat-Resistant, Durable Engineering Plastic or Metal |

| Data Output Options | USB / SD Card Export (model-dependent) |

| Usage Environment | Suitable for industrial SMT assembly lines |

Understanding What a Wave Checker Does

Wave soldering involves passing a PCB over a molten wave of solder to attach components. But even minor fluctuations in temperature, wave height, or speed can result in poor joints, solder bridges, or cold soldering. That’s where the Wave Checker plays a vital role.

A Wave Checker is a specialized measuring instrument that:

-

Monitors wave soldering process parameters in real time

-

Detects inconsistencies in solder wave height and temperature

-

Provides data for quality control, optimization, and troubleshooting

This tool is particularly valuable in mass production settings, where hundreds or thousands of PCBs must meet consistent quality benchmarks every day.

Key Functions of the Wave Checker

Real-Time Monitoring

Equipped with digital LCD displays, Wave Checkers provide live readings of:

-

Wave height variations

-

Solder temperature fluctuations

-

Solder contact time on PCBs

Real-time tracking ensures immediate detection of anomalies, which can be corrected before impacting a large volume of production.

Accurate Process Verification

By using sensors and calibration modules, the Wave Checker helps verify if the machine is operating within defined soldering parameters. This helps:

-

Reduce process-related defects

-

Improve quality control records

-

Support audits and traceability documentation

Data Logging and Export

Depending on the model, users can store wave soldering data on an SD card or transfer it via USB to external systems. This helps in:

-

Maintaining production reports

-

Comparing performance across shifts or batches

-

Tracking maintenance effectiveness

Where the Wave Checker Fits in Your SMT Line

The Wave Checker is used during scheduled quality inspections or after preventive maintenance on wave soldering machines. It serves multiple industries, such as:

-

Consumer electronics manufacturing

-

LED PCB assembly plants

-

Automotive electronics production

-

Industrial automation boards

-

Medical device assembly

It becomes especially critical during new product introduction (NPI) or when scaling up from prototyping to mass production.

Key Advantages of Kaasu Enterprises’ Wave Checker

1. Process Optimization

By providing accurate feedback on wave parameters, the device helps engineers fine-tune conveyor speeds, wave height settings, and solder pot temperatures for better solder joint quality.

2. Defect Reduction

Eliminating guesswork helps minimize bridging, skipping, or insufficient soldering—common issues in through-hole processes.

3. Consistency in Results

Maintaining uniformity across batches is critical for customer satisfaction and regulatory compliance. Wave Checkers ensure repeatable process quality.

4. Ease of Use

With intuitive displays, rugged design, and easy calibration, this tool is operator-friendly and low-maintenance.

5. Robust Design

Made with heat-resistant and durable materials, the Wave Checker withstands the extreme environment of wave soldering equipment.

How to Use the Wave Checker Effectively

Here’s a simple guideline for operational use:

-

Preheat the machine to normal operating temperature

-

Place the Wave Checker in the same path as a PCB would pass

-

Observe real-time readings on the display for wave height, contact time, and temperature

-

Export the data via USB or SD card for record-keeping or analysis

-

Compare against standard operating parameters and make machine adjustments if necessary

Operators and process engineers can use this data to make informed changes that enhance performance, especially during process validation or troubleshooting.

Common Parameters Measured by Wave Checker

The following are among the most commonly tracked values:

-

Solder Wave Height – Ensures that the component leads are fully immersed

-

Solder Pot Temperature – Too low causes cold joints, too high risks component damage

-

Dwell Time – The time PCBs are in contact with the molten solder

-

Thermal Gradient – Important for heat-sensitive components

Maintaining these within specified limits ensures perfect solder joints with minimal rework.

Integration with Quality Control Systems

Wave Checkers are not standalone tools—they play a vital role in your factory’s QC ecosystem:

-

Supports ISO and IPC quality standards

-

Helps align with Six Sigma and lean manufacturing principles

-

Facilitates automated QC reporting systems

Many models are compatible with statistical process control (SPC) software or can be manually integrated into internal reporting formats.

Custom Packaging and Support

Kaasu Enterprises ensures:

-

Protective packaging for transport and storage

-

Optional accessories, like calibration jigs, USB cables, SD card readers

-

User manuals and operator training guidance

We also provide after-sales support and technical help for integration, maintenance, and usage best practices.

Why Choose Kaasu Enterprises?

As a trusted name in SMT equipment and solutions, Kaasu Enterprises stands for:

-

Consistent quality across all products

-

Industry-specific customization

-

Competitive pricing for volume buyers

-

On-time delivery across India

-

Responsive customer support

Whether you’re a contract manufacturer, OEM, or electronics startup, we offer tools that scale with your production needs.

Conclusion –

In the complex process of wave soldering, consistency is key. With a Wave Checker from Kaasu Enterprises, you can measure, control, and optimize your soldering process like never before. From verifying wave height to ensuring solder temperature consistency, this compact device empowers your team to maintain high standards of quality—batch after batch.

With accurate data output, durable construction, and real-time monitoring, the Wave Checker becomes an essential part of your SMT line’s quality assurance toolkit.