Conformal Coating

Supplier in Delhi | Kaasu Enterprises

Conformal Coating

Product Details –

| Parameter | Description |

|---|---|

| Product Name | Conformal Coating |

| Category | SMT Product |

| Function | Protective coating for PCB to prevent moisture, dust, chemicals & temperature |

| Application | Electronics Assembly, PCB Surface Protection |

| Coating Type | Acrylic / Silicone / Polyurethane / UV Curable (based on variant) |

| Appearance | Transparent or Slightly Tinted |

| Drying Method | Air Dry / Oven Cure / UV Cure |

| Key Features | High insulation, moisture resistance, chemical protection, easy inspection |

| Coverage | ~5–10 m² per liter (depending on thickness and method) |

| RoHS Compliance | Yes |

Conformal Coating: Kaasu Enterprises offers premium conformal coatings in Delhi, providing essential protection for electronic circuits against moisture, dust, and environmental damage.

Kaasuenterprises Provide The Best high quality Equipments, Tools, consumables and Materials for the Electronics manufacturing

Kaasuenterprises, we are dedicated to empowering industries by providing cutting-edge technological solutions that enhance productivity, efficiency, and product quality. Recognizing the pivotal role electronics play in today’s business landscape, we strive to be your trusted partner for all electronic equipment and accessory needs.

Additional Information:

Conformal Coating – Essential Protection for PCB Assemblies

In the world of modern electronics, the need to safeguard circuit boards against environmental hazards is greater than ever. Whether devices are exposed to humidity, dust, temperature fluctuations, or chemical exposure, it’s critical to ensure their long-term reliability. This is where Conformal Coating steps in as an indispensable solution.

Kaasu Enterprises provides industry-grade Conformal Coatings in Delhi, designed specifically to protect printed circuit boards (PCBs) and electronic assemblies during operation and storage. Our coatings offer not only physical insulation but also protection against harsh environmental factors that can compromise circuit performance.

Product Snapshot –

| Parameter | Details |

|---|---|

| Product Name | Conformal Coating |

| Category | SMT Product |

| Function | Protective Layer for PCB Circuitry |

| Application | Electronics Assembly, PCB Surface Protection |

| Coating Types | Acrylic, Silicone, Polyurethane, UV Curable |

| Appearance | Transparent / Slightly Tinted |

| Drying Method | Air Dry / Oven Cure / UV Cure |

| Coverage | 5–10 m² per liter (varies with method & thickness) |

| Key Features | High Insulation, Moisture & Chemical Resistance, Visual Inspection |

| RoHS Compliance | Yes |

Understanding What Conformal Coating Is

A Conformal Coating is a thin, protective chemical film applied to PCBs and other electronic components. It “conforms” to the shape of the board and its components, creating a uniform protective barrier. This coating is essential in preventing short circuits, corrosion, or performance failures due to environmental factors.

Common threats that conformal coating protects against include:

-

Humidity and moisture

-

Dust and debris

-

Temperature extremes

-

Chemical vapors

-

Mechanical vibrations

This makes conformal coating a vital part of electronics used in industries like automotive, aerospace, consumer electronics, telecommunications, and industrial automation.

Types of Conformal Coating Available

At Kaasu Enterprises, we offer various coating chemistries to match diverse operational requirements:

Acrylic-Based Coatings

-

Easy to apply and remove

-

Cost-effective

-

Fast drying at room temperature

Silicone-Based Coatings

-

Excellent flexibility and thermal resistance

-

Ideal for high-temperature environments

-

Good moisture and salt spray resistance

Polyurethane Coatings

-

Strong chemical and abrasion resistance

-

Durable with good dielectric strength

-

Suitable for harsh industrial surroundings

UV Curable Coatings

-

Rapid curing under UV light

-

Highly transparent for easy inspection

-

Great for automated application lines

Each type serves a distinct purpose depending on the operational environment and desired protection level.

Application Areas of Conformal Coating

Conformal Coating is widely used across multiple sectors of the electronics industry. Key areas include:

-

Consumer Electronics – Mobile phones, TVs, audio devices

-

Automotive PCBs – Dashboard units, engine control modules, sensors

-

Medical Equipment – Imaging devices, monitoring tools

-

Industrial Control Systems – PLCs, VFDs, automation panels

-

Defense and Aerospace – Radar systems, avionics, guidance circuits

Whether in humid regions or high-vibration environments, conformal coating is vital for extending product lifespan and reducing maintenance or replacement costs.

How Conformal Coating Enhances PCB Durability

1. Moisture and Humidity Resistance

Conformal coatings prevent moisture ingress that can cause electrical leakage or corrosion of solder joints.

2. Electrical Insulation

With high dielectric strength, coatings ensure that close-packed components don’t create unintentional current paths.

3. Corrosion Prevention

Protects metal leads, traces, and joints from corrosion due to environmental contaminants.

4. Mechanical Stress Absorption

In high-vibration environments, flexible coatings like silicone can absorb shocks and reduce mechanical fatigue on solder joints.

5. Contamination Protection

Guards against dust, chemicals, oils, and flux residues that may degrade PCB performance.

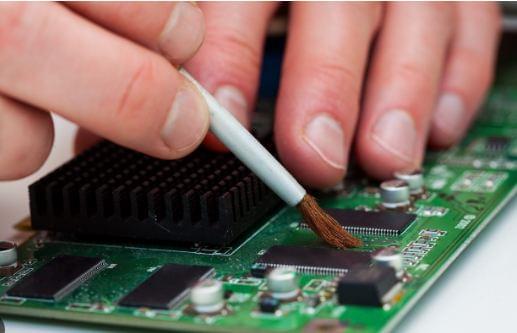

Methods of Application

Depending on the volume and precision required, conformal coating can be applied using several techniques:

-

Brushing – Manual method ideal for rework or small batches

-

Spraying – Aerosol or spray gun use for even surface coverage

-

Dipping – Boards are immersed for complete coverage (ideal for bulk processing)

-

Selective Coating (Robotic) – Automated system that applies coating to precise areas, leaving connectors untouched

Each method has its own use case, and Kaasu Enterprises can recommend or supply the right formulation for your preferred process.

Inspection and Testing

Post-application, the coating must be inspected to ensure uniform coverage and thickness. Some coatings are UV-traceable, making them visible under UV light for quick inspection.

Common inspection criteria include:

-

No bubbles or pinholes

-

No coating over connectors (unless specified)

-

Consistent thickness

-

No peeling or flaking after drying

We also suggest adhesion and insulation resistance testing to confirm coating integrity in demanding applications.

Curing and Drying Options

Different formulations of conformal coating have different curing needs:

-

Air Drying – Used for acrylic and silicone types, requiring 30 minutes to several hours

-

Oven Curing – Speeds up drying and improves adhesion

-

UV Curing – Fastest curing (within seconds), best suited for automated lines

At Kaasu Enterprises, we guide customers in selecting the right coating for their production flow—balancing efficiency and reliability.

Packaging and Coverage Information

Conformal coatings are supplied in:

-

Bottles (250 ml / 500 ml)

-

Cans (1L / 5L)

-

Custom packaging for high-volume buyers

With coverage ranging between 5 to 10 m² per liter, usage efficiency depends on:

-

Application method

-

Desired film thickness

-

Surface complexity of PCB

Why Choose Conformal Coatings from Kaasu Enterprises?

-

Trusted Quality – Our coatings are made from reliable, industrial-grade materials

-

RoHS Compliant – Ensuring eco-friendly, lead-free formulations

-

Technical Guidance – Our team helps choose the right coating for your application

-

Bulk Availability – Suited for small units or mass production lines

-

PAN India Supply – Quick delivery across manufacturing hubs

With Kaasu Enterprises, you gain more than just a product—you get a long-term partner for your electronics protection needs.

Conclusion –

When your PCB assemblies are exposed to moisture, heat, chemicals, and dust, using a Conformal Coating becomes essential—not optional. It’s the invisible layer that guards your electronics silently yet powerfully, ensuring durability and reliability even in the harshest environments.

At Kaasu Enterprises, we provide high-performance conformal coatings in different formulations tailored to meet specific industry requirements. From simple air-drying acrylics to advanced UV-curable options, we help you protect your circuit boards effectively and affordably.