Solder Paste

Supplier in Delhi | Kaasu Enterprises

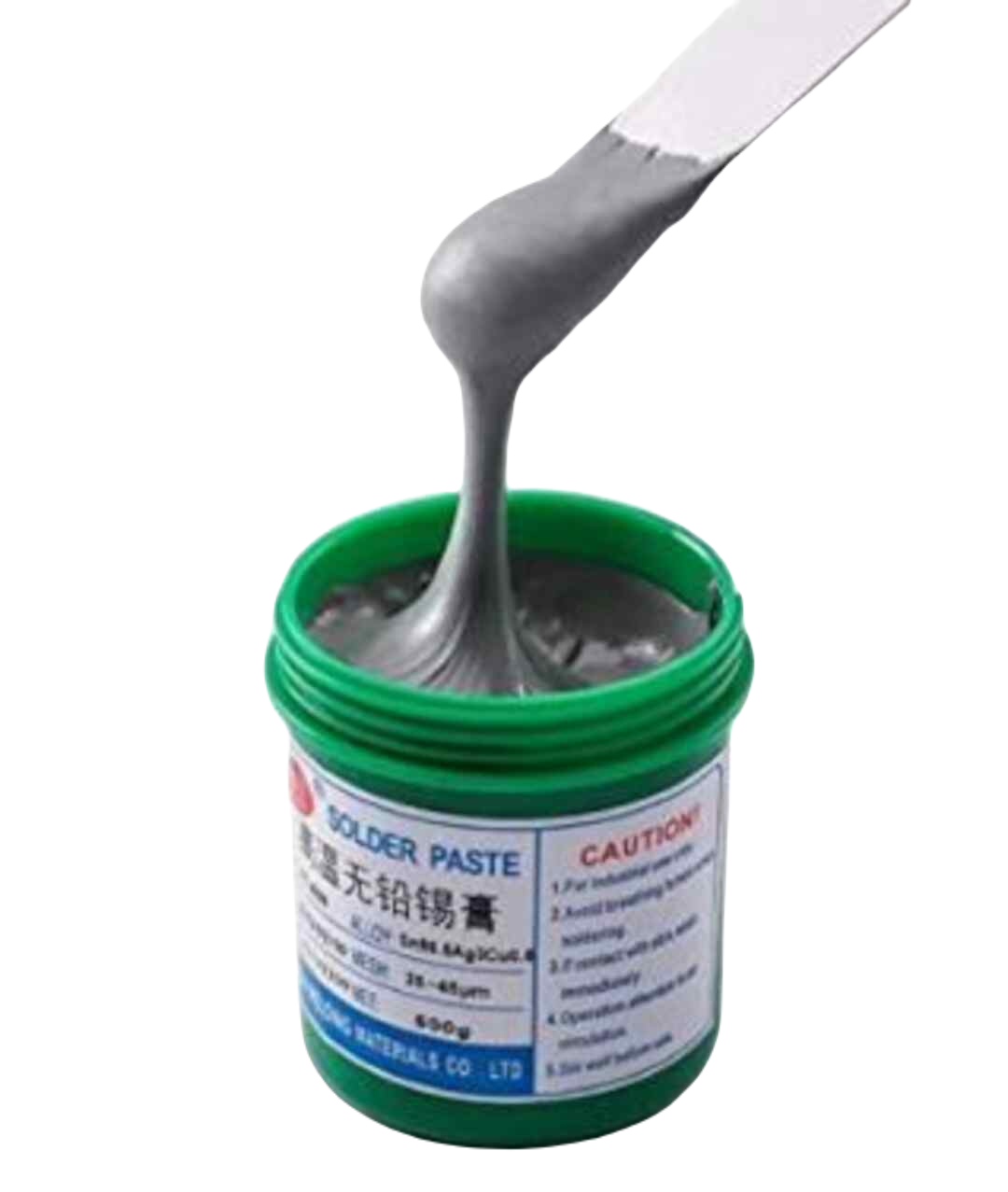

Solder Paste

Product Details –

| Parameter | Description |

|---|---|

| Product Name | Solder Paste |

| Category | Soldering Stations & Accessories |

| Type | Powdered solder suspended in flux paste |

| Usage/Application | Ideal for surface-mount (SMT) applications via stencil printing, dispensing, etc. |

| Key Features | Excellent solder joint formation, sticky texture holds components during placement |

| Packaging/Weight | Sourced in standard quantities suitable for SMT lines (specific packaging varies) |

Solder Paste: A mixture of solder and flux used in surface mount technology for effective soldering.

Additional Information:

Solder Paste – The Essential Glue of Modern SMT Assembly

In today’s fast-paced electronics manufacturing world, high-precision surface-mount technology (SMT) assembly depends heavily on reliable solder paste. The Solder Paste offered by Kaasuenterprises combines powdered solder alloy and flux to form a sticky, shape-retaining medium essential for component placement and solder joint formation. Whether you are running a single-station reflow setup, a medium-scale SMT line, or a stencil-printing operation, quality solder paste is the backbone of every reliable assembly.

A strong solder paste enables neat paste deposition, secure component pickup, and flawless reflow on printed circuit boards. Let’s explore this indispensable product and discover why it’s a game-changer in electronics assembly.

Product Details –

| Parameter | Description |

|---|---|

| Product Name | Solder Paste |

| Category | Soldering Stations & Accessories |

| Type | Powdered solder suspended in flux paste |

| Usage/Application | Ideal for surface-mount (SMT) applications via stencil printing, dispensing, etc. |

| Key Features | Excellent solder joint formation, sticky texture holds components during placement |

| Packaging/Weight | Sourced in standard quantities suitable for SMT lines (specific packaging varies) |

What Is Solder Paste?

Solder paste is a blended semi-fluid material composed of:

-

Finely powdered solder alloy (e.g., Sn96.5/Ag3.0/Cu0.5 or lead-free alternatives)

-

Activated rosin-based flux to remove oxidation

-

Thixotropic vehicle that ensures stability until reflow

It holds components in place and melts during reflow to form strong solder joints, making it essential for automated SMT production.

Solder Paste in the SMT Workflow

Once applied via stencil or syringe, the process flows as follows:

-

Stencil Printing

A vinyl or stainless steel stencil deposits small amounts of paste onto PCB SMD pads. -

Component Placement

Sticky paste holds components like resistors and ICs in position during placement. -

Reflow Process

Heat melts the solder particles, bonding the component leads to PCB pads. -

Cleaning (Optional)

Flux residue may be cleaned using alcohol or specialized cleaning solutions post-reflow.

Each stage relies on consistent paste behavior for quality outcomes.

Why Choose Kaasuenterprises’ Solder Paste?

Optimized Alloy Composition

Formulated for superior wetting, joint strength, and temperature stability—whether using lead-based or lead-free alloys.

Precision Particle Sizes

Fine powders (Type 3 and 4) ensure excellent stencil transfer and clean apertures, especially for fine-pitch components.

Flux Chemistry

Designed to minimize spattering during stencil or dispensing processes, while fully activating during reflow to remove oxides.

Consistent Viscosity and Tack

Precisely balanced rheology prevents paste from slumping and guarantees efficient component adhesion.

Moisture-Ready Packaging

Sealed cartridges or jars protect paste from humidity, and refrigerate storage preserves shelf life.

Core Performance Characteristics

| Feature | Why It Matters |

|---|---|

| Alloy Type | Determines joint strength and regulatory compliance |

| Flux Activity Level | Defines post-reflow residue and cleaning ease |

| Particle Size | Flourishes in fine-pitch vs. larger pad environments |

| Tack Force | Keeps SMDs in place before reflow |

| Viscosity Range | Enables smooth dispensing and reduced clogging |

| Reflow Profile Response | Ensures paste reflows elegantly without process issues |

Kaasuenterprises formulates its paste to excel across these key performance domains.

Advantages of Quality Solder Paste

Strong Bond Formation

Produces reliable electrical and mechanical connections with high tensile strength.

Controlled Solder Volume

Minimizes risk of bridging, tombstoning, or excessive solder buildup.

High Reflow Reliability

Stable under repeated thermal cycles, with predictable solderability.

Cleaner Process

Low-void, low-residue performance, meeting quality control requirements.

High Throughput Potential

Fast reflow and strong pickup translate to improved production speeds.

Practical Applications

Mass SMT PCB Assembly

Ideal for automated stencil printing and IR/reflow oven assembly of consumer electronics.

Prototype and R&D Builds

Enables quick assembly for design verification or lab builds.

Rework and Repair

Ideal for selective soldering or patch rework using paste dispensing.

Mixed Technology Boards

Applies paste to through-hole pads for wave-soldering or manual touch-up.

How to Use Solder Paste Properly

-

Storage and Pre-conditioning

Refrigerate and thaw paste to room temperature before use. -

Proper Stencil Techniques

Maintain stencil flatness, clean abrasively after each shift. -

Consistent Printing

Adjust squeegee pressure and speed for smooth paste film application. -

Accurate Component Placement

Ensure pick-and-place head picks components correctly prior to reflow. -

Controlled Reflow Cycle

Follow recommended thermal profile to melt solder and activate flux fully. -

Post-Reflow Cleanliness

Clean residue if necessary, inspect joints optically, and wash PCBs as needed.

Comparing Different Types of Solder Paste

| Type | Particle Size Range | Best For |

|---|---|---|

| Type 3 | 25–45 μm | Standard-pitch components |

| Type 4 | 20–38 μm | Fine-pitch parts like BGAs |

| Type 5 | 15–25 μm | Very fine-pitch and small chips |

Kaasuenterprises supplies multiple paste types to accommodate diverse PCB needs.

Troubleshooting Common Issues

-

Bridging on Small Pads: Switch to finer Type 4/+ paste and refine squeegee settings.

-

Tombstoning: Adjust thermal ramp and squeegee speeds.

-

Voiding: Optimize preheat and soak zones.

-

Solder Balls: Reduce flux activity level and tweak stencil design.

These actions ensure consistent defect reduction on production lines.

Maintenance & Handling Tips

-

Regularly Stir Paste to maintain suspended particles.

-

Clean Cartridge Nozzles to prevent flow issues.

-

Store as per Temperature Guidelines to preserve reactivity.

-

Use within Shelf Life for best results.

-

Monitor Paste Weight and Volume during production runs.

Correct handling ensures consistent results and minimal waste.

Why Kaasuenterprises Leads in Solder Paste Quality

-

Rigorous Testing: Each batch is evaluated for transfer efficiency and wetting performance.

-

Technical Backing: Real-world profile and process optimization support.

-

Batch Traceability: Lot numbers help maintain consistency across production runs.

-

Packaging Options: Supplies small lab packs to multi-kilo reel-support kits.

-

Responsive Distribution: Quick stock replenishment across India.

Kaasuenterprises ensures you receive confident, production-ready materials when needed.

Conclusion –

From securing components before reflow to ensuring neat joints after, solder paste has become the catalyst for modern SMT assembly. Kaasuenterprises’ formulation supports precision, speed, and yield—meeting the high expectations of electronics manufacturing and rework alike. No matter your operation size, from one-off hand assemblies to multi-station production lines, investing in quality solder paste is a small step that pays dividends in consistency, reliability, and repeatability.

The future of SMT assembly and repair depends on dependable solder paste. With Kaasuenterprises’ Solder Paste, you gain superior tackiness, precise deposition, strong joints, and clean reflow every time. Elevate your electronics performance—choose a product engineered for excellence in modern SMT workflows.