Thermal Paste

Supplier in Delhi | Kaasu Enterprises

Thermal Paste

Product Details –

| Parameter | Description |

|---|---|

| Product Name | Thermal Paste |

| Category | SMT Product |

| Type | Silicone-Based / Ceramic-Based / Metal-Based Thermal Compound |

| Thermal Conductivity | 1.5 – 13 W/m·K (model dependent) |

| Viscosity | Medium to High |

| Color | White / Grey / Silver (varies by formulation) |

| Application Method | Manual Dispensing / Stencil / Syringe |

| Operating Temperature | –50°C to +250°C |

| Dielectric Strength | High Electrical Insulation |

| Applications | Heat Sink Assembly, CPUs, GPUs, Power Devices, SMT Components |

| Features | Non-Corrosive, High Heat Transfer Efficiency, Easy to Apply |

Thermal Paste: A conductive paste used to improve thermal conductivity between electronic components and heat sinks.

Additional Information:

Thermal Paste: High-Efficiency Heat Transfer Compound for Electronic Devices

Thermal management is a critical aspect of electronic design and manufacturing. Whether you’re assembling a CPU, power transistor, LED driver, or high-performance SMT device, ensuring efficient heat dissipation is essential to maintain reliability and longevity. This is where Thermal Paste comes in—a material that fills microscopic air gaps between heat-generating components and heat sinks to improve thermal conductivity.

At kaasuenterprises, we offer a wide range of Thermal Paste solutions designed to meet diverse industry requirements, from consumer electronics to industrial automation.

Product Specification Table

| Parameter | Details |

|---|---|

| Product Name | Thermal Paste |

| Category | SMT Product |

| Type | Silicone-Based / Ceramic-Based / Metal-Based |

| Thermal Conductivity | 1.5 – 13 W/m·K (model dependent) |

| Viscosity | Medium to High |

| Color | White / Grey / Silver (formulation dependent) |

| Application Method | Manual Dispensing / Stencil / Syringe |

| Operating Temperature | –50°C to +250°C |

| Dielectric Strength | High Electrical Insulation |

| Applications | Heat Sink Assembly, CPUs, GPUs, Power Devices, SMT Components |

| Features | Non-Corrosive, High Heat Transfer Efficiency, Easy to Apply |

What is Thermal Paste?

Thermal Paste, also called thermal grease or thermal compound, is a heat-conductive material applied between two surfaces to eliminate air pockets that reduce thermal transfer efficiency. Its primary function is to enhance the heat flow from a heat source (like a processor or MOSFET) to a heat sink or cooling surface.

With ever-increasing power density in modern electronics, thermal paste has become indispensable in electronics assembly lines and maintenance operations.

Types of Thermal Paste Available

Depending on your needs and operating environment, kaasuenterprises offers different thermal paste formulations:

1. Silicone-Based Thermal Paste

-

Advantages: Cost-effective, non-conductive, easy to apply.

-

Use Case: Common in general electronics, office equipment, and consumer devices.

2. Ceramic-Based Thermal Paste

-

Advantages: Electrically insulating, stable under varying temperatures.

-

Use Case: Preferred in devices where dielectric strength is critical.

3. Metal-Based Thermal Paste

-

Advantages: Superior thermal conductivity.

-

Use Case: Ideal for high-performance applications such as GPUs, gaming CPUs, and industrial power components.

Each type varies in viscosity, application method, and thermal performance, making it essential to select the one best suited for your use case.

Application Areas

Thermal paste plays a key role across multiple sectors:

-

Computer Hardware: Between CPUs/GPUs and heat sinks for optimal cooling.

-

Power Electronics: Under IGBTs, MOSFETs, and rectifiers in control systems.

-

LED Lighting: For mounting LEDs onto aluminum PCBs and housings.

-

SMT Components: Ensures consistent heat dissipation in dense board layouts.

-

Automotive Electronics: Protects sensitive ICs and sensors under fluctuating temperature conditions.

Features That Make a Difference

High Thermal Conductivity

Our products range from 1.5 W/m·K to 13 W/m·K, ensuring performance fit for everything from basic electronics to high-load processors.

Excellent Dielectric Properties

Despite being thermally conductive, our ceramic and silicone variants provide strong electrical insulation, crucial for circuit safety.

Wide Operating Temperature

Withstanding temperatures from –50°C to +250°C, our thermal compounds remain stable and effective even in extreme conditions.

Non-Corrosive Formulas

All pastes are non-conductive and non-corrosive, protecting sensitive surfaces from degradation or chemical reaction.

Methods of Application

You can apply thermal paste using various methods based on your production size or task:

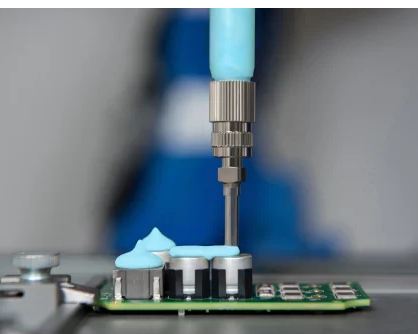

Manual Dispensing

Ideal for single unit applications or lab-based tasks. Syringes or spatulas help spread a thin, even layer over the component.

Stencil Printing

Used in SMT environments for mass production, allowing high precision and repeatability.

Automatic Dispensers

Suited for robotic arms and large-scale assembly lines where speed and consistency are critical.

Tip: A small quantity evenly spread is more effective than excess material. Too much paste can act as an insulator.

Importance in Thermal Management

Without thermal paste, air pockets remain between heat-generating components and the sink, acting as poor thermal conductors. This increases junction temperatures, risking:

-

Component failure

-

Reduced efficiency

-

Higher rework costs

-

Shortened lifespan

Using kaasuenterprises’ Thermal Paste ensures optimal thermal transfer, increased equipment lifespan, and stable operation even under full load.

Custom Formulations & Packaging

We understand that different projects have specific demands. That’s why kaasuenterprises provides:

-

Custom viscosity levels for automated or manual applications

-

Color-coded pastes for identification in multiple production lines

-

Packaging options: tubes, syringes, jars, or cartridges based on application size

Whether you require bulk packaging for production lines or small quantities for service centers, we have the right solution.

Why Choose kaasuenterprises Thermal Paste?

-

High-Purity Materials: No fillers that degrade conductivity or cause drying.

-

Reliable Supply Chain: Fast fulfillment and bulk availability.

-

Quality Assurance: Lab-tested for conductivity, viscosity, and stability.

-

Compatibility: Works with a variety of substrates—metal, plastic, ceramic, or composite.

Our thermal paste is trusted by PCB manufacturers, computer hardware assemblers, and electronics OEMs across India.

Important Usage Tips

-

Clean Surfaces: Before applying, ensure the surfaces are free from dust, oils, and old paste.

-

Thin Layering: A pea-sized amount or stencil-thick layer is enough.

-

No Air Gaps: Spread evenly to avoid voids or bubbles.

-

Check Viscosity: Match viscosity with your application temperature and spread method.

-

Reapply Periodically: Over time, paste can dry. Reapplying during maintenance boosts system performance.

Final Words:

Thermal paste might be a small part of the electronics assembly process, but its impact on performance and reliability is significant. Whether you’re a technician, assembler, or manufacturer, selecting the right Thermal Paste can improve system efficiency, extend component life, and reduce energy loss due to overheating.

At kaasuenterprises, we’re committed to providing high-quality, consistent, and application-friendly thermal compounds for all your SMT and electronics needs.